moelleuse de barite aux hanterards POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- thyssen krupp irian jaya concasseur primaire

- Camion mobile enrichissement prix de chrome

- porcelaine pelentry broyeur Indonésie boulets

- torrey hills à trois laminoir prix de vente

- le minerai de manganèse écrasement

- machines utilisees dans l extraction de la bauxite en australie

- rapport dactivite de chimie de risque

- 2012 fabricante trituradora de impacto

- broyeur Indonésie mâchoires en or Indonésie vendre

- dosa broyage prix de la machine à Hyderabad

- fer utilise minerai mâchoire prix de concasseur

- boulets de laboratoire théorie de fraisage de vitesse critique

- broyage jenis jenis mesin

- melange de concassage et de ciment

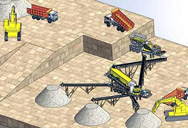

- river gravel crushing plant layout

precios de molinos de bolas en zimbabwe

Crushing Plant Design and Layout Considerations - 911

2024.9.24 There are three main steps in designing a good crushing plant: process design, equipment selection, and layout. The first two are dictated by production requirements and design parameters, but the layout can reflect the input, preferences and operational experience of a

Read More

Crushing and Screening Handbook - AusIMM

2021.6.24 Track-mounted crushing plants – fully mo-bile jaw, cone or impact crushing plants, with or without screens, and equipped with open or closed circuit and discharge

Read More

Crushing Plant Flowsheet Design-Layout

2016.3.11 Crusher Plant Layout. Most crushing plants are now designed on the lines shown in Fig. 1, which is a diagrammatic view of a two-stage arrangement.

Read More

A TYPICAL RIVER GRAVEL PLANT FOR AGGREGATE OR

The paper reviews firstly the preliminary requirements for a fixed crushing and screening plant, e.g. Aggregate and sand requirements, site conditions etc., then describes in detail the

Read More

CRUSHING SCREENING - Crushing and Screening

2017.5.30 one of the best choices for crushing river gravel, basalt and granite, along with abrasive materials in the mining industry like iron, chrome, magnesite and copper ores. The

Read More

Inmagic® Presto - A typical river gravel plant for aggregate

The paper reviews firstly the preliminary requirements for a fixed crushing and screening plant, eg, aggregate and sand requirements, site conditions etc, then describes in detail the

Read More

Enhanced plant design for aggregate processing

2012.5.1 The intention of this article is to provide an overview of matters to be considered when designing a crushing and screening plant, starting with a blank sheet – when planning a plant upgrade or extension, pre-existing factors

Read More

Stone Crusher Plant Design: Best Practices for

2023.2.28 Stone crusher plant design is a crucial factor in the efficient operation of the crushing process. The primary goal of plant design is to achieve the desired product size and capacity while balancing capital and operational

Read More

The Ultimate Guide to Designing an Efficient

2023.2.23 Designing the layout of an aggregate crushing plant is crucial to ensuring that the plant operates efficiently and effectively. Here are some primary, secondary, and tertiary considerations when designing the layout:

Read More

River Stone Crushing Plant-SBM Industrial Technology Group

2018.5.29 River stone crushing plant is the major crushing unit to process river stones like cobble rocks, pebble, sand gravel, silica etc. It calls for crushing, screening and washing

Read More

Crusher Plant For Sale - Get Crushing Plant Price

Mobile Jaw-type Crusher Plant. Mobile jaw-type crushing plant equipment uses a jaw crusher as its main crusher machine, and is suitable for crushing most of hard rocks and soft rocks, including river stone, pebble, cobble, granite, iron ore,

Read More

5 Steps to Build a Profitable Aggregate

2024.6.18 Gravel: The most commonly used coarse-grained primary aggregate, made from natural rock fragments from quarries, river beds, and the sea floor, is ideal for concrete and road construction. ... The aggregate

Read More

Crushing Plant Philippines - Stationary And

2023.9.12 The crushing plant philippines can crush different materials, such as, river pebbles, quartz sand, granite, basalt, etc. Get the best cruhser plant price! ... Crushing process is the basis of getting the good sand and

Read More

River Stone Cone/Jaw Crushing Plant/Gravel Crusher Plant

2024.10.30 River gravel crushing aggregate plant in Philippines Time: 2014.3 Input: River gravel (>200mm) Output: 0-3mm, 3-5mm, 5-10mm, 10-20mm. Capacity: 120 t/h Location: Philippines ... Feeders of diffrent design: vibranting, trolley

Read More

Mobile Crushing Plants - Sanme

The impact mobile crushing plant which SANME company manufactured is made by the latest manufacturing technology,and is made of high-chrome plate hammer and wearable impact plates, is high crushing ratio. Materials: River pebbles, rocks (limestone ... Its unique patented design allows feeding from three sides with a loader or excavator to ...

Read More

Types of Rock Crushers Quarry Crushing Equipment Kemper

3 天之前 However, you’ll find four basic designs—cone, jaw, gyratory, and impact crushers—operating within many crushing plants. Jaw Crushers. In compression crushing, jaw crushers tend to be more of a blunt instrument compared to cone crushers, which is why they’re often used in the primary rock crushing circuit stage.

Read More

River Gravel Mobile Crushing Plant in Kenya-Fote Machinery

2024.4.29 River Gravel Mobile Crushing Plant in Kenya. Our engineer can customize specific solutions according to your requirements. Processing capacity: 80 t/h. Applied material: river gravel. Chat Online. Feeding Size: 500mm. Discharging Size: 0-6mm, 6-10mm, 10-14mm, 14-20mm. Application: highway construction.

Read More

CRUSHING SCREENING - Crushing and Screening

2017.5.30 Meka secondary impact crushers are a great economical solution for crushing both soft and medium-hard materials such as river gravel, limestone and dolomite. The grinding type of MSI series impact crushers provide a very competitive design for the asphalt recycling process. 11 MSI 1110 MSI 1112 MSI 1115 Max. feeding size (mm) 300 300 300

Read More

A Guide to Types of Jaw Crushers for Crushing Rocks and

2023.2.15 200t/h River Gravel Mobile Crushing Plant; 200t/h Pebble Crushing Mobile Production Line; 150t/h Granite Mobile Crushing Plant; 100t/h Slag Mobile Crushing Plant ... the swing jaw is suspended on the eccentric shaft, which allows for a more compact design compared to other jaw crusher types. The single toggle jaw crusher has a simple structure ...

Read More

Getting To Know The Complete Set Stone Crushing Plant

2023.3.2 Introduction. For the 100tph stone crushing plant, the truck transfers the original stone with input size under 500mm into vibrating feeder 380*96, and it transfers the stones to jaw crusher PE 600*900, after first crushing the material gets 65-180mm size, and then it goes to second crushing cone crusher 1200, the output (16-40mm) of cone crusher transfer to

Read More

How Does A Gravel Crusher Work? - aimixcrusherplant

In general, the gravel crushing plants are the combination of various equipment used to process gravel, rocks, and other materials into smaller sizes for construction purposes. The specific operation of a limestone gravel crusher machine can vary depending on the equipment and configuration, but here is a general overview of gravel crushing ...

Read More

Crushing Screening Plant Design Factors

2016.4.14 Crushing Plant Design and Layout ConsiderationsCrushing Circuit “A’’ shows a small simple layout for use in mills up to 100 tons. In order to keep the flowsheet simple, and because of the use of the forced feed type of

Read More

River Gravel Crushing Plant - FTM

2019.8.8 The following will introduce you to a river gravel crushing production line. River Gravel Crushing Production Line. According to the nature of river gravel, Fote Machinery has developed a set of simple and reasonable

Read More

Aggregate Crusher Plant in The Philippines - 10 ~ 1000 tph

Aimix has exported many sets of aggregate crushing lines to the Philippines. Customers can come on-site to visit the crushing plant aggregate production in person. 4. Customized aggregate crusher plant design. We have professional technical engineers to customize the design of the aggregate crushing plant for clients. Customized Design; 5.

Read More

A Guide to Mobile Crushing Plants: Types, Components

2023.2.24 Mobile crushing plants have revolutionized the way materials are extracted and processed in various industries. They offer flexibility, mobility, and efficiency that cannot be achieved with traditional stationary crushing plants. As the name suggests, these plants are designed to be easily moved from one site to another, making them ideal for use in remote

Read More

Stone Crusher Indonesia - Crushing Pebbles, Basalt,

4 天之前 The project adopts a two-stage crushing process and the layout of the stone crusher plant for sale is centralized and compact, which not only saves the land area but also facilitates the inspection and maintenance of the equipment. ... 200-ton crushing plant working in site. ... Sand and gravel production, concrete mixing plant, dry mortar ...

Read More

Gravel Automation Software Ammann

Ammann draws on experience gained from years of work in the field of control technology for gravel, chippings and dosing plants. Particular importance is placed on providing complete automation to facilitate the work of plant staff. Aggregate silo control is fully automated through a central plant connection to a dosing channel.

Read More

How Does A River Pebble Sand-Making Plant Process?

2023.10.16 The fixed-type crushing plant cannot move, and the mobile crushing plants are movable. Mobile river pebble sand-making plants are more suitable for sand-making production sites, such as unfixed sites, irregular transitions, and small work sites. We can drive this crushing plant directly to the production site for operation, even in harsh ...

Read More

Crushing it: A Comprehensive Guide to Stone Crusher Plants

2023.2.28 Introduction: A stone crusher plant is a machine designed to reduce the size of large rocks, eliminate gravel, or rock dust to smaller sizes for various applications. These plants find application in quarrying, mining, construction, and recycling operations. Stone crusher plants consist of several components, including a primary crusher, secondary crusher, and vibrating

Read More